FAQ

Q: What is Turbo-K Gas Turbine Compressor Cleaner?

A: It is a water-based and non-hazardous gas turbine compressor cleaner that is specially designed for on-line (hot wash) and off-line (cold wash) cleaning of gas turbine compressors.

Q: What is the difference between “on-line cleaning” and “off-line cleaning”?

A: On-line cleaning is conducted with the gas turbine at operating temperature and off-line cleaning is conducted with gas turbine in a cooled state utilizing cranking speed. Off-line cleaning can be effective in restoring most of the lost performance but it is a very time consuming process that requires the shutdown of the gas turbine. This means that there will be loss of revenue during the period of shutdown. There is no engine shutdown for on-line cleaning, thus there will be no interruption to production or operation routines.

Q: Why should a power plant operator be interested in gas turbine on-line and off-line cleaning?

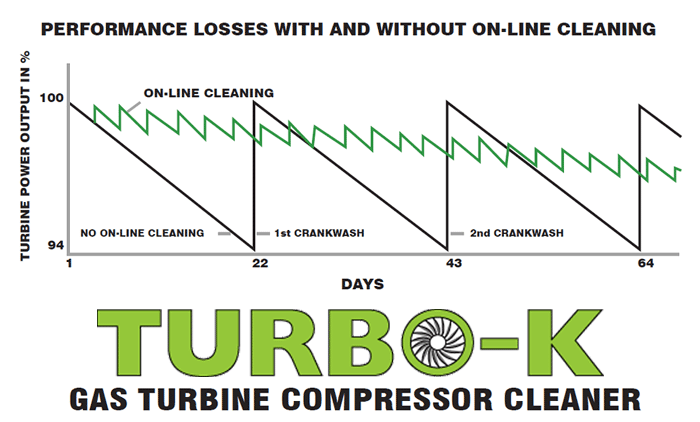

A: Washing of gas turbine compressors is known to provide the most effective method for preventing gas turbine compressor fouling. It ensures maximum available power output, improved fuel efficiency and reduced wear and tear on machine components such as bearings and blades. The period between necessary shut-downs for off-line cleaning can be significantly extended by on-line cleaning (hot washing) thus reducing costly downtime and production losses. The following chart illustrates the performance losses with and without on-line cleaning.

Q: What are the features of Turbo-K Gas Turbine Compressor Cleaner?

A: There are at least six major benefits that come only with Turbo-K Gas Turbine Compressor Cleaner:

- It is non-hazardous, water-based, non-corrosive, non-toxic, non-flammable and biodegradable with no Alkyl Phenol Ethoxylates (a-p-e), Nonyl Phenol Ethoxylates (n-p-e) and other ingredients with aquatic toxicity in its formulation.

- It has proven outstanding performance in on-line washing as product has no “cloud point” temperature and thus exceptional dirt suspension abilities so that all fouling is carried into the combustion chamber to be expelled.

- It has inherent corrosion inhibiting properties to further protect the compressor against possible corrosion.

- It has been used by all leading gas turbine manufacturers such as Rolls Royce, General Electric, Pratt & Whitney, etc.

- It is supplied as an industry standard 1:4 concentrate. A Ready-To-Use Turbo-K product is also available.

- There are no shipping restrictions for the product.

Q: Why is Turbo-K Gas Turbine Compressor Cleaner more effective than others?

A: Turbo-K product containing a very complex and triple active formula of cationic, non-ionic and amphoteric surfactants is totally immune against the known “cloud point” phenomenon of conventional surfactant cleaners. Upon exceeding the cloud point temperature, other gas turbine compressor cleaners using common surfactant ingredients drop the dirt removed from front stages onto latter stages of the compressor, causing the fouling to redeposit downstream, hence a less satisfactory on-line washing performance. This brings our product to a level that other gas turbine compressor cleaners cannot match.

Q: What is the gas turbine compressor cleaner volume required for on-line and off-line cleaning?

A: Each OEM details the required volume for both on-line and off-line cleaning. Typically, a 35 MW gas turbine will require around 150 liters of gas turbine compressor cleaner in RTU (Ready-To-Use) for on-line cleaning.

Q: What are the typical cycles for on-line and off-line cleaning?

A: On-line and off-line cleaning cycles are detailed in the OEM manual.

Q: How do you select the right cleaning chemicals?

A: Water alone cannot remove greasy hydrocarbon deposits on engine components and its use may lead to corrosion problem. The use of gas turbine compressor cleaners made from flammable hydrocarbon solvents results in severe damage to the seals, bearings and metals used in the engine. Water-based gas turbine compressor cleaners, while safer on engine seals, etc. are based on non-ionic surfactants that tend to have limited detergency and soil suspension properties. Turbo-K is the only cleaner that is based on a complex formulation relying on synergism, where two, three or more detergents work together in synergy. Turbo-K's soil removing properties and exceptional suspension abilities ensure that what is removed stays removed. This alliance means that Turbo-K continues to clean right down through the compressor without re-depositing foul particles collected during the cleaning process. As explained previously Turbo-K has no “Cloud Point Temperature”, which means the detergent will not come out of the solution when it is heated. Thus, Turbo-K Gas Turbine Compressor Cleaner is more cost effective and performs much better than other water-based gas turbine compressor cleaners when used for on-line cleaning.

Q: Where is the Turbo-K product distributed?

A: The product is distributed globally through our agents and distributors.